Supporting Quorn's production facility with

low-carbon electricity, hot water and steam

Quorn, part of the Monde Nissin Corporation, is the UK’s number-one meat-free brand with annual sales of around £150m.

The challenge

As the first global brand in its sector to achieve Carbon Trust certification of its carbon footprint figures, Quorn Foods wanted to guarantee the energy needs essential for the production facilities and reduce carbon emissions.

The solution

With the focus on further reducing carbon footprint, Veolia designed and installed a 2MWe CHP unit and combination boiler that provides low-carbon electricity, hot water and steam to the production facility at Stokesley, North Yorkshire. To ensure electrical connection of the CHP went smoothly, the Veolia team was closely involved with suppliers and the Electricity Board.

To support production processes, the CHP runs 24-hours a day and is operated and maintained using Veolia’s Integrated Management System, which provides remote monitoring and control 365 days a year. A comprehensive maintenance service, provided by Veolia’s nationwide service teams, guarantees availability to ensure the Quorn production facility gets the energy supplies it needs.

The Veolia CHP is one of the new lean-burn units that deliver the high electrical efficiency required to support this production process. By harnessing the heat produced in the generating process and reducing transmission over long distances by being site-based, the CHPs save energy and carbon emissions. This makes them typically twice as energy efficient as grid-supplied electricity and separate heat plant.

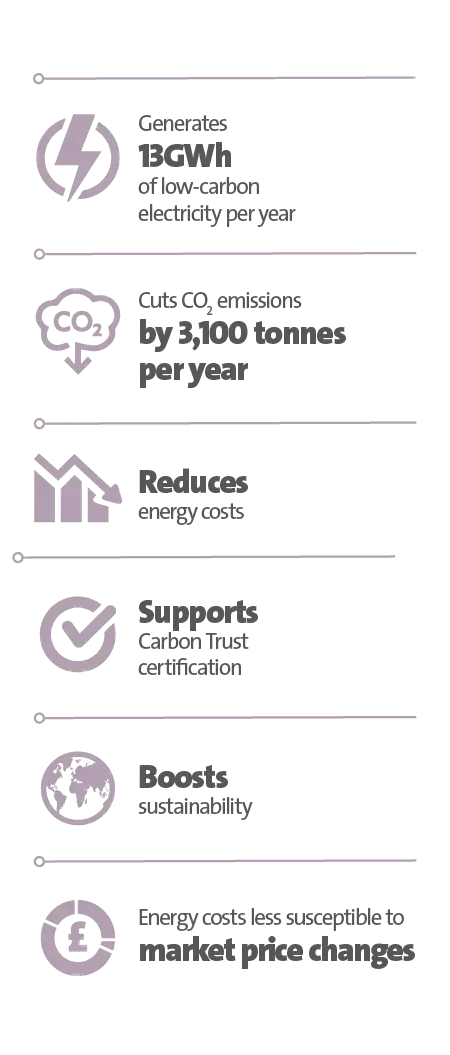

Value delivered

The carbon savings contribute to Quorn’s sustainability goals and secure the energy supplies to the production facility. By displacing import grid electricity, the CHP plant on site provides more resilience for other grid users.

Do you have a challenge similar to Quorn?