Improve safety and reduce downtime with automated Column, Tower & Vessel Cleaning

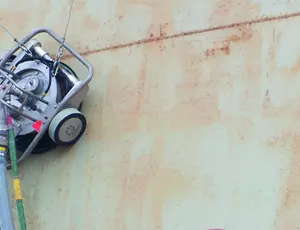

Safety is paramount when cleaning in confined spaces. With almost no need for man entry, our automated cleaning solution improves safety, reduces downtime and complies with confined space regulations.

How we can help?

We’ve been cleaning columns, towers and vessels within industrial premises for more than thirty five years, and as market leaders we understand exactly what is required from a technical and regulatory perspective. Our automated high flow and high-pressure equipment enables us to efficiently and effectively clean your plant items, minimise your downtime and reduce the need for confined space entry. It’s a cleaning method that is safer for operators and reduces the time it takes to clean, minimising the impact that essential maintenance has on your operations.

This cleaning method is now used extensively on shutdowns at oil refineries throughout Europe and is also used regularly across a wide range of industrial sectors.

How do we create value for you?

We offer a range of innovative, tailored solutions to meet your individual needs, delivered by a team of highly trained, experienced technicians.

Automated cleaning is a very effective and efficient method that drastically reduces downtime. Where no confined space entry is required, higher pressure can be used to improve the quality of the cleaning and fewer operators are needed to complete the task, reducing health and safety risks. What’s more, our service ensures that you will comply fully with relevant health, safety and environmental legislation. We have a number of non entry methods available such as manway cannon, telescopic boom and tank cleaning head assemblies to meet your individual needs.

Our automated cleaning equipment cleans with:

-

Working pressure up to 1000 bar

-

240 litres per minute flow

-

Hot water at up to 80⁰C, supplied from our own water units

-

Manway cannon and tank cleaning heads

-

Range of multi-lance and tank cleaning attachments available