Long-term energy and cost savings with P43® submerged Rotary Jet Mixer

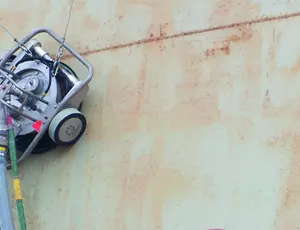

Tackling sludge in crude oil storage tanks can be costly and time-consuming. Our pioneering P43® submerged Rotary Jet Mixer is a well-proven sludge control and tank blending device for larger diameter cylindrical tanks. Designed to work from the existing fill line, it requires no power source to operate and minimal maintenance, resulting in significant long-term energy cost savings.

How do we create value for you ?

Periodic use of the P43® totally eliminates the need for side entry propeller mixers, which results in substantial electrical cost savings and gives you a fast payback time of just two to three years. Add to that a typical maintenance cycle of 15 years between services the P43® really is a fit and forget solution to your tanks needs. In addition to supplying the P43® from new, Veolia also provides full lifecycle support by offering a full sevice of any existing machines; with full replacement of any worn parts the machines are returned fully refurbished, tested and under a 12 months warranty.

How it works

Powered entirely by the flow of fluid through the machine, the P43® rotates and directs a submerged jet of crude oil across the bottom of the storage tank. This dissolves and re-suspends any sludge that has accumulated throughout the oil overhead, enabling you to recover valuable hydrocarbons rather than letting them go to waste. The P43® can be centre mounted on an existing inlet pipe or placed at the tank wall using the existing tank shell manway for mounting. Both configurations provide complete sludge control with just 24 hours of operation each month.

Our P43® Submerged Rotary Jet Mixer:

-

Maintains maximum storage capacity

-

Provides considerable cost savings due to reduced tank outage

-

Provides complete sludge control with just 24 hours of operation per month

-

Needs no electricity or separate power (operates from existing feed pump)

-

Requires minimal maintenance with the units typically operating 15 years between services

-

Eliminates water trapping to minimise tank floor corrosion repairs