We're proud to have achieved over 1 million hours worked without lost time injuries

Turnkey Demolition Solutions

At KDC Veolia, we understand demolition requires a delicate approach and with our innovative, precise demolition techniques, we minimise disturbance and maximise asset recovery. We keep manual intervention to a minimum by using mechanical means such as precision demolition, involving semi-remote working, reducing risk and providing a quick turnaround.

We are your trusted demolition and dismantling contractor in high-hazard, high-risk sectors, such as nuclear, oil and gas, petrochemical, and pharmaceutical.

Our approach to Demolition

KDC Veolia's decontamination and demolition methodology is based on mechanical means, only uses manual intervention in a safe and stable environment. Our customers choose us based on our SHE approach and always remaining commercially competitive.

1 Process

Advanced material processing and recycling by initial on-site evaluation

2 Segregation

Careful segregation, selective salvage, initial cleaning and removal

3 Reuse

We unveil the value of redundant equipment under controlled conditions

4 Prioritise

Resource recovery reduces the environmental impact in preparation for resale operations

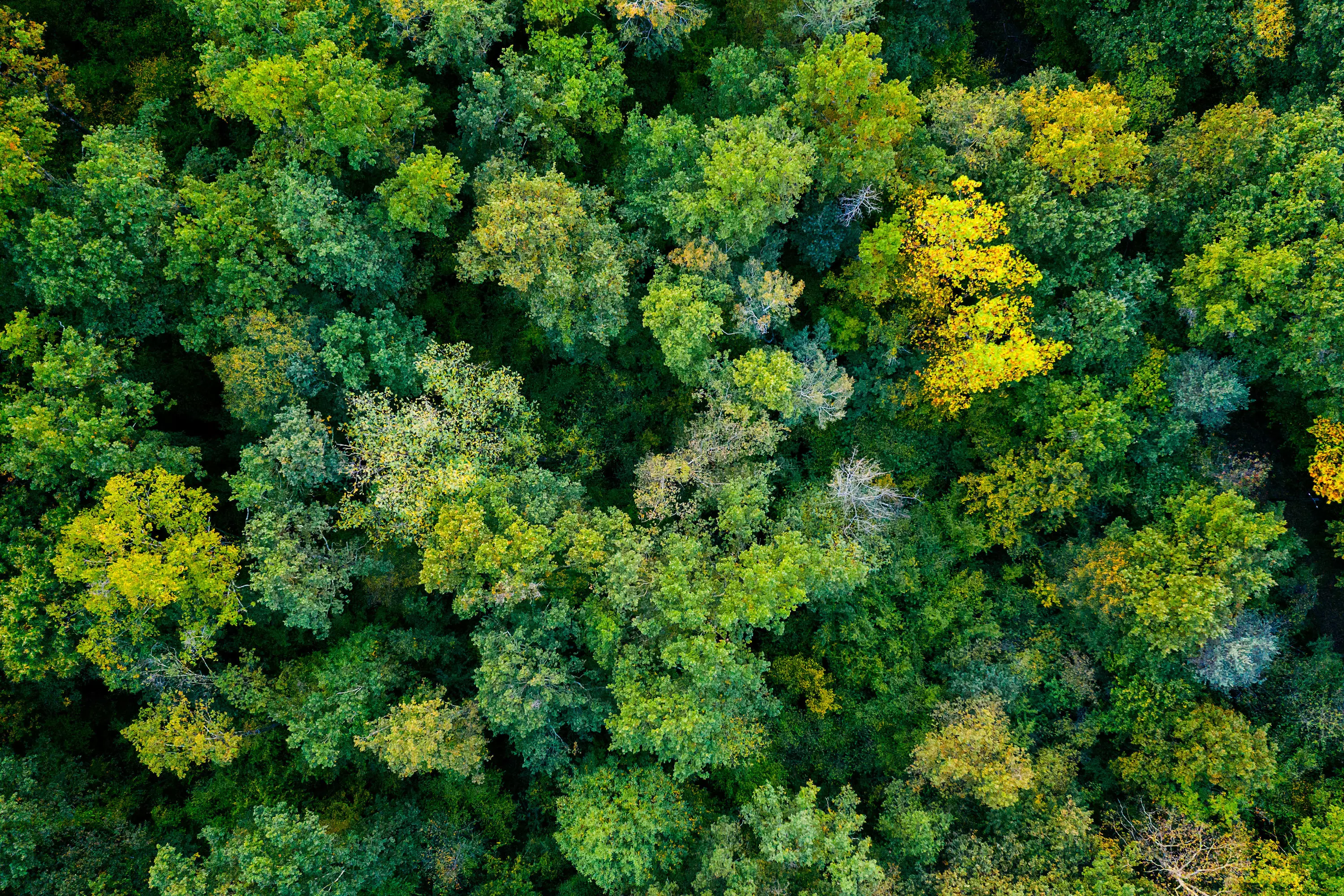

How we recycle and reuse our demolition materials

As an accredited member of NFDC, we are required to recycle a minimum of 95% of waste, but we go further than that. Our established processes mean that we consistently achieve recycling rates exceeding 98%.

Ensuring that valuable resources are recovered and the environmental impact is minimised. While returning valuable resources to the supply chain.

We employ innovative strategies and established partnerships through risk and sustainability providers like EcoVadis. This enables us to utilise the value of salvaged materials and support our clients’ sustainability goals.

Reduced Project Costs

Reduce your project costs through efficient material recovery and recycling

Sustainability Profile

Enhance your sustainability profile with documented waste reduction

Civil Nuclear

Chemicals & Pharmaceuticals

Oil & Gas: Onshore

Oil & Gas: Offshore

Defence

Energy, Utilities & Industrial (EUI)

Our Accreditations

Our Demolition Projects

Read our Case Studies to see more of our successful demolition projects, and view plans from start to finish across sectors. Find out how we can be the solution for your business.

Highlighting our planning, execution, commitment to safety and protecting the environment.

Client Testimonials

How do you plan and execute demolition in operational or congested industrial sites?

Demolition in live industrial sites requires 1) Pre-work mapping of live services, critical equipment and operational zones through physical inspection and as-built drawings, 2) Development of hour-by-hour sequencing aligned with production schedules, 3) Installation of dust/debris containment systems to protect adjacent processes, 4) Use of mini excavators and robotic demolition units in space-restricted areas, 5) Real-time vibration and noise monitoring to prevent disruption, 6) Mobile dust suppression units and immediate material removal to maintain site cleanliness, 7) Daily coordination meetings with plant managers to adjust work zones based on shifting operational needs

What is your approach to sequencing demolition works to minimise disruption to ongoing plant operations?

We schedule demolition activities to align with planned plant maintenance periods and utilise off-peak hours between 8 PM and 4 AM and weekends when production levels drop. Our zone-by-zone removal sequence, backed by physical barriers protecting active equipment and regular update meetings with operations staff, keeps plant disruption to a minimum.

What protocols do you follow for the safe removal of hazardous plant components, such as tanks, silos, or chimneys?

Our protocol begins with detailed surveys and material testing, followed by developing specific method statements for each component. We utilise specialised equipment and PPE, implement proper decontamination procedures, and ensure all materials are disposed of through licensed arrangements.

How do you integrate demolition works with subsequent site redevelopment or remediation plans?

We engage early with development teams to ensure seamless integration, carefully preserving required infrastructure and documenting underground services. Our approach includes strategic management of recyclable materials and close coordination with environmental consultants throughout the project lifecycle.

Partner with KDC Veolia for services you can trust