The manufacturing company of the future?

Advancing new materials and narrowing gaps in international labour costs will create a level playing field for innovation.

Trend #1 | Hyper-efficient business models

Trend #1 | Hyper-efficient business models

Manufacturing businesses will need to be increasingly adaptive to prosper, thinking harder about how, where and what they make.

Relocating around customers and resources

Businesses will need to think about resource use, consumption and transport costs. Manufacturers will have to decide whether to be closer to raw materials to guarantee supply or closer to customers to meet demand.

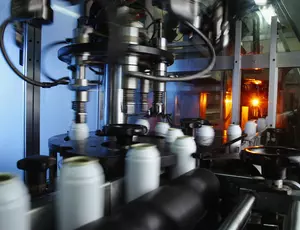

Adaptable production lines

Factories will increasingly be able to create a range of different products by physically reconfiguring to meet changing demand.

Selling benefits, not products

A circular economy requires keeping resources in use for as long as possible, before deconstructing and re-engineering them to create new products. Today manufacturers only monitor products for the warranty period. In the future, more manufacturers will retain ownership and responsibility for their products and their ongoing performance. Customers will buy the benefits, not the product.

Trend #2 | New generation materials

Trend #2 | New generation materials

Today's technologies are limited by old materials. Future materials will be lighter, stronger and greener, providing new opportunities for innovation.

Biological materials

The need for greener products that are cheap, strong and plentiful will lead to new perspectives on naturally sourced materials. Manufacturing cars uses significant resources, expensive tooling and excessive energy. Phoenix, a concept car designed by Albrect Birkner and Kenneth Cobonpue, challenges convention by using lightweight and natural materials, such as bamboo, on a frame that is built by hand using minimal tools and energy.

Technological alternatives

Research and development will lead to more lightweight yet durable materials providing manufacturers with the opportunity to produce structures using less material and energy.

Waste as a tradeable asset

The concept of waste will be radically different in 2050. Manufacturers will see by-products as something of value that they can sell to other businesses or exchange for credit.

Trend #3 | Rise of robotics

Trend #3 | Rise of robotics

Industrial robots are on the verge of revolutionising manufacturing. As they become smarter, faster and cheaper they'll be called upon to do even more.

A new era of efficiency

As humans move off the production lines and into new engineering roles, factories will be able to operate longer, faster, more safely and with less waste – making way for greater productivity and quality assurance.

Kurion, part of Veolia, creates technology solutions to access, separate and stabilise nuclear and hazardous materials and to safely isolate them from the environment. Through robotics, Kurion eliminates human risk in some of the most dangerous environments imaginable.

Connected thinking

Through the Internet of Things (IoT), data capture will greatly benefit industry. Advanced analytics platforms could enable manufacturers to evaluate big data sourced from connected robotics to improve processes. Sensors will transmit data to alert and initiate preventative maintenance and adjust production speeds according to the market.

Onshoring

The advance of robotics could reinvigorate UK manufacturing, making local production more cost effective than importing. Robotics developments will level the playing field and reduce the advantage enjoyed by China and other low-cost markets. This is already leading to some ‘reshoring’ of UK production, especially in textiles, an industry particularly affected by emerging markets.