Minimising environmental

emissions for CF Fertilisers UK

CF Fertilisers UK, the UK’s largest fertiliser manufacturer, produces nitrogen for fertilisers used in agriculture. The Billingham operation consists of an ammonia plant, three nitric acid plants, a carbon dioxide plant and an Ammonium Nitrate (AN) Fertiliser Plant.

The challenge

To maintain its production process, CF Fertilisers UK requires stable high volume supplies of steam and is also responsible for supply of steam to other manufacturing companies on the Billingham site. The steam supply is also used to drive CF Fertilisers UK’s own 50MW turbo generator.

The solution

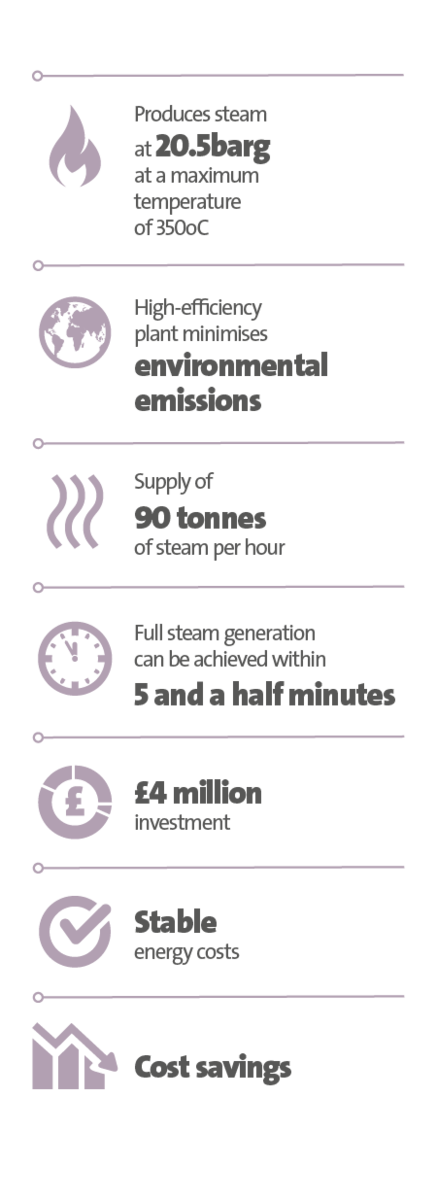

In 1998, with mounting operational costs and the varying reliability of the existing plant, CF Fertilisers UK decided to look at different options to maintain the steam supply. The best solution to guarantee this supply was to build a new energy plant capable of generating large volumes of steam at high pressures, and for this plant to provide a rapid delivery of steam on interruption or failure of the site supply.

To achieve this, CF Fertilisers UK signed an energy management agreement with Veolia to design, build and subsequently operate and maintain a new steam generation facility. As part of the agreement, Veolia invested £4million to cover the construction of the plant, which included the installation of the largest shell boilers in the UK.

Value delivered

The energy centre supplies the essential steam supply for CF Fertilisers UK which ensures it can supply other steam users on the Billingham site and meet its own needs. CF Fertilisers UK benefited from the design, rapid installation and operational expertise from Veolia’s teams who support this site application on a 24/7 basis.

Do you have a challenge similar to the CF Fertilisers UK?