CO2 and cost reductions

for Kraft Heinz Company

The Kraft Heinz Company site at Kitt Green is Europe’s largest food canning plant. It processes 1.34 billion cans of food every year, including the well-known Kraft Heinz Company 57 products such as baked beans. The site processes food on a 24 hour, 6-day shift throughout the year.

The challenge

To maintain production processes, Kraft Heinz Company require up to 99 tonnes of steam per hour. To improve environmental performance, reduce fuel consumption and sustain the steam supply, they wanted a new energy centre, capable of generating large volumes of steam. A key driver was optimising the use of technology.

The solution

Veolia is an energy specialist which examines businesses in precise detail to ensure a guaranteed supply of sustainable, efficient energy is delivered with budget certainty.

Veolia designed, built, operates and maintains a new 100 MWth steam generation facility, the largest and most efficient of its type serving European industry.

The latest software and computer control systems enable the facility to operate unmanned, with 24 hour monitoring by Veolia’s Site Monitoring Centre, supported by mobile engineers.

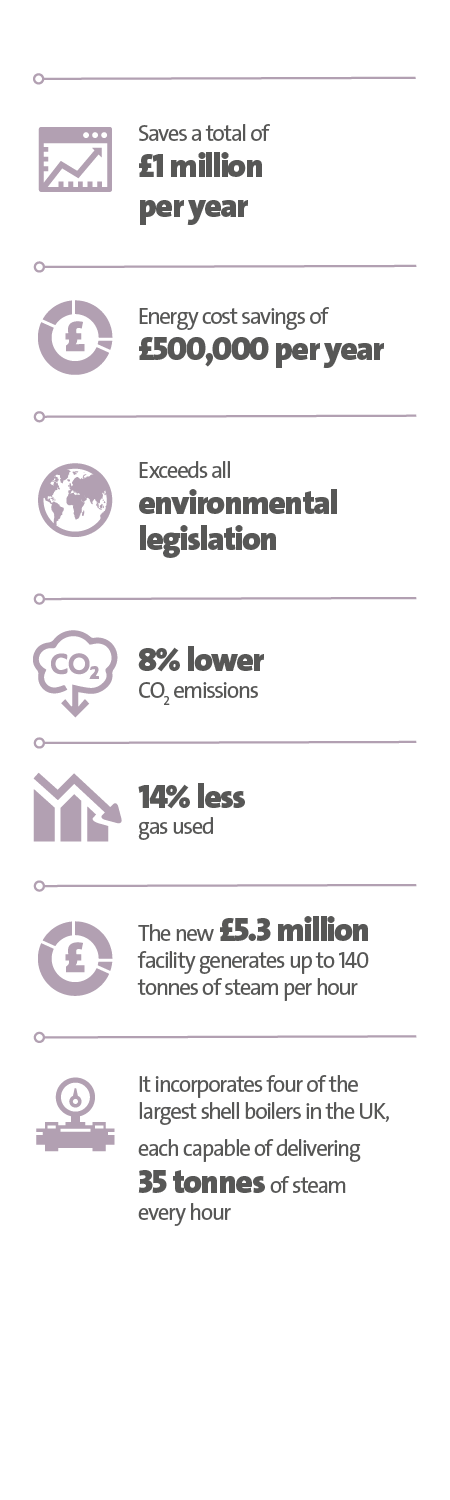

Value delivered

Veolia guarantees the steam supply, maintaining it 24/7 at the required pressure and temperature to support year round production. Veolia’s Replacement Guarantee Scheme also ensures that there are no unbudgeted steam plant replacement costs during the contract.

Do you have a challenge similar to Kraft Heinz Company Ltd ?